Milling of Pulses

Milling of Pulses

What is milling?

Pulses are mostly consumed in the form of dehusked splits, commonly known as dal. The outer layer of the grain (husk) is attached to the protein and starch bearing cotyledons of the pulse grains. In some grains like pigeonpea, mungbean and urdbean, this bonding is strong due to the presence of a layer of gums in between the husk and the cotyledons. These are known as difficult-to-mill pulses. In other grains like chickpea, pea, lathyrus etc., this bonding is comparatively weaker. Such grains can be milled easily and are categorized as easy-to-mill pulses. This outer husk layer is required to be separated from the cotyledons and subsequently split in two halves before consumed as dal. The process of removal of husk from the cotyledons is called dehusking and the entire process of dehusking and subsequent splitting of cotyledons, its cleaning, polishing and grading is known as milling. Dehusking improves product appearance, texture, product quality, palatability and digestibility. A substantial amount of avoidable loss takes place at different stages of milling. This may vary from 10-15% depending upon the type and quality of grain milled, the process and machinery used for milling and other factors. It is, therefore, important to look at different aspects of milling so that proper process and machinery are used to obtain maximum recovery of good quality dal from the grain and take corrective measures to reduce milling losses to the minimum.

Pulse milling is the third largest food processing industry after rice and flour milling. An estimated 75% of pulses produced are processed for making dal in mills of different capacities.

Milling of pulses involves two major steps:

- loosening of husk and

- removal of husk and splitting into cotyledons with the help of suitable machine.

Home scale milling

This involves pounding of grains for dehusking by using a mortar and pestle after mixing with small quantity of water and drying in the sun for a few hours. Sun-drying after water application helps to loosen the husk from the cotyledons. In mortars, dehusking is achieved due to shearing action between pestle and grains, and abrasive effect between the grains. Once the pounding is done for several minutes, the husk gets detached from the grains. Winnowing separates husk and split cotyledons are separated from the whole dehusked and unhusked grains by manual sieving. The whole grains are again pounded for further dehusking and splitting. This technique of dehusking is generally adopted when small quantity i.e., up to 5 kg of pulses is to be dehusked. Dal yield by this process is quite low (50-60%) due to breakage and chipping of the edges of cotyledons.

Cottage scale milling

Traditionally, villagers use the hand operated wooden or stone chakki/ sheller when comparatively large quantities of pulses are to be dehusked. The technique is similar to those of the home-scale methods. The preconditioning of grains before milling is done either by prolonged sun drying until the hulls are loosened or through application of water followed by several hours of sun drying and tempering. The heating of the grains in pan with or without sand along with vigorous stirring is also in practice. The duration of treatment depends upon the variety of pulses to be milled. There are no standard dehusking techniques at the cottage level. Different combinations of methods, depending upon the experience and available facilities, are followed. Of late, mechanized shellers and plate mills are used for custom milling of preconditioned pulses. At cottage level milling, often the husk is not completely removed and breakage is also quite high. This reduces the consumer appeal and value of the product. The yield of head dal obtained from these techniques may very in the range of 55-70% depending upon the variety of pulse and pre-treatment used.

Commercial scale milling

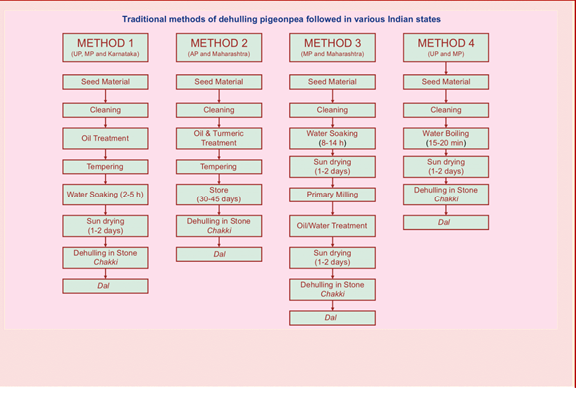

Commercial scale milling involves processing large quantities of pulses in plants of bigger capacities. Even though, the basic milling procedure is similar, specifics of dehusking methods vary widely from one dal mill to another dal mill and region to region. Two methods for large scale processing or pulses are in practice. Traditional method, most commonly followed by dal millers, is almost similar to cottage level treatment in principles. A modern method of milling has been developed at CFTRI which is independent of weather conditions.

Traditional milling

It has already been said that the milling process varies from mill to mill and region to region and no standard or common process is in practice. The sequence of operations like pre-milling treatment, conditioning, dehusking, and splitting is normally common. Large variation exists in the steps followed in milling but basic unit operations remain the same.

Milling process

Essentially milling process involves cleaning, grading, pitting, treatment milling and polishing operations. Usually milling processes are described for the toughest to mill pulse grains i.e., pigeonpea. The major steps involve in pulse milling are discussed below:

Cleaning and grading

It involves removing dust, dirt, foreign material, off sized, immature and damaged grains and grading in two or more fractions to process separately.

Pitting

Use of emery-coated roller is a common practice in commercial dal mills. The emery coating is used for abrasive or refractory action. Whole pulses are passed through abrasive roller machine for scratching of seed to facilitate the entry of oil/water in the grain during pre-milling treatment.

Pre-milling treatments

The treatment is given for loosening of husk from cotyledons, which is attached through a gum layer is called pre-milling treatment. Mostly premilling treatments are developed for pigeonpea. Water soaking, oil and water application, mixing of sodium bi-carbonate solution and thermal applications are commonly recommended and adopted pre-milling treatments. For commercial milling in large capacity dal mills, oil and water treatment is commonly adopted, whereas for household milling, water treatment is popularly used.

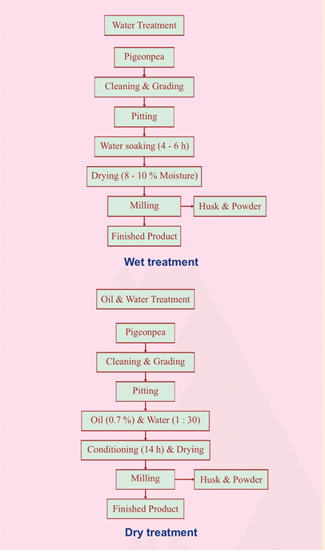

Different methods are employed in different regions depending upon type of grain. This also varies from mill to mill. Pre-treatments can be broadly classified into i) wet treatment and ii) dry treatment.

Wet treatment

In this method of treatment, soaking and drying are considered as effective technique to loosen the husk. This method has the advantage of facilitating dehusking and splitting the cotyledons, giving less breakage. This can be attributed to lower deshusking percentage of grains in water treatment process. However, it has the disadvantage of being weather dependent and labour intensive. Dal produced by this method cooks better but takes longer time to cook. Commonly adopted red earth treatment is considered as wet method. In this method, grains are thoroughly mixed with a paste of red earth after soaking in water for about 12 hours and heaping for about 16 hours. The grains are spread in thin layer in drying yards for 2–4 days. When dried, the red earth is removed by sieving and the grains are then milled on power operated stone or emery coated vertical chakki to yield dal.

Dry treatment

Dry milling treatment is reported to produce dal that cooks faster, however, losses due to broken and powdering are high. In dry method, oil/water application followed by drying are important steps in processing of pulses.

In this process, after cleaning and grading, grains are pitted and then mixed with about 1% oil (linseed), thoroughly and spread for sun drying in thin layer, for 2–3 days. At the end of drying, 2-5% of water is sprayed, mixed thoroughly and tempered for overnight. Tempered grains are dehusked in roller machines to give dehusked grains and dal.

Tempering

Once the pre-milling treatment is given, conditioning is done to have uniformity of treatment throughout the grain mass. This process gives time for better penetration of oil/water beneath the seed coat to dissolve gums.

Drying

In most of the mills in India, sun drying method is commonly practiced. Grains are spread in thin layer on pucca floor under the sun and stirred frequently with rake/feet for even drying. This operation makes process of dal milling a very lengthy requiring (2-3 days). In this case, sun-dried grains require more passes and consumes more energy. The drying time with the use of dryers ranges between 2-3 hrs, which results in tremendous time saving. Dryers are used in few mills that too in rainy seasons for drying of treated grains.

Dehusking and splitting

Dal mills by and large use emery rollers for dehusking and splitting. In case of pigeonpea, more than 3 passes are required for complete milling. Other pulses take one or two passes in emery mill in order to achieve maximum milling. The physical, chemical and structural strength of grain coupled with the functional and mechanical characteristics of processing units jointly play an important role. Grain properties such as hardness, load deformation behaviour, shape, size density and variety of grain etc. have considerable effect on dal yield. The machine parameters such as roller speed, clearance, emery size etc. have vital role to play on dal recovery. As a result of milling, unhusked and dehusked whole grains, split cotyledons, broken, husk and powder are obtained. Whole grains are passed again for further dehusking and/or splitting after water treatment. Husk and powder produced during milling is generally separated with the help of aspirator and are used as cattle feed.

Polishing

Polishing is done to increase consumers appeal and is a form of value addition, though not desirable. Dal is polished in different ways, such as nylon polish, oil/water polish, leather and makhmal polish. Generally polishing is done using soap stone, oil or water. Polishing gives uniform look and shine to each grain.

Advances in Milling Technology

As pigeonpea grains are most difficult-to-mill, most of the researches about pre-milling treatments and pulse milling were confined to pigeonpea only. Until recently, few pre-milling treatments viz., heat, chemical, enzyme etc., were tried at various research organizations for milling of pigeonpea. However, oil and water treatment is most prevalent in modern dal mills. Water soaking followed by sun drying is commonly adopted at rural level pigeonpea processing.

Traditionally water/oil treatments are given for loosening of husk. These traditional pre-milling techniques are labour intensive, wasteful and weather dependent. Attempts have been made by various Research and Development institutions to develop improved processes for pre-treatment of pigeonpea in order to achieve efficient and economic milling of pulses. Research outcome of different organizations conducted on pigeonpea grain are as under :

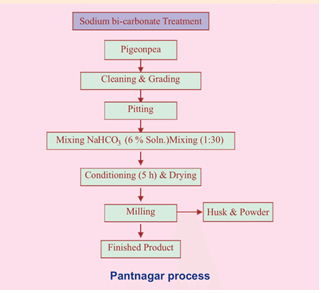

Pantnagar process (Chemical treatment)

In this method, cleaned and graded pigeonpea grains are treated with 10 per cent sodium bicarbonate solution mixed in the ratio of 30:1. These grains are then heaped for 5 hours at 30 °C followed by drying under the

sun. The tempered and dried grains are passed through rollers. Pantnager process utilizes traditional milling machinery. The milled product is cleaned and graded with a blower, cyclone separator and grader. It is claimed that if pre-milling treatment is properly given, 91-95% dehusking is achieved in single pass having 4-5% whole grain. The husk, broken and powder are removed separately. The gota (dehusked whole grain) obtained is mixed with 2-2.5% water and kept for 4 hours for tempering. These grains are passed through splitter for dal making. It has also been observed during the tests conducted that 80–90% of total Sodium content is removed with husk and powder. Whereas the remaining traces of sodium in dal improves its cooking quality and storage characteristics. The dal recovery has been claimed as 80%. Advantage of this method is that it eliminates the use of oil. But the problem with this method is that the chemical solution goes with the husk and this may be harmful to cattles, if used as cattle feed.

Pantnagar process (Enzymatic treatment)

At Pantnagar, milling experiments were conducted on enzyme treated pigeonpea grains at different combination of pre-treatment parameters such as moisture content of seed, incubation period and temperature. The results obtained indicated that enzymatic pre-treatment has positive effect on hulling efficiency. Hulling efficiency of untreated grains was found to be 60.82%, while the same for enzyme and water treated grains was achieved at 89.68 and 73.90%, respectively. It has been pointed out that high amount of powder formation during dehusking of pigeonpea have sizeable impact on its availability. The enzyme treatment not only increases the hulling efficiency but also reduces the amount of powder formed. The effect of enzyme concentration on hulling efficiency was also studied. Besides, it has also been claimed that enzyme treatment improves digestibility of dal protein and reduces cooking time.

CIAE process

Cleaned and graded pigeonpea grains are fed in a roller mill for scratching. The clearance between the outer screen cage and inner abrasive roller is fixed and maintained throughout the process. Once the scratching is over, then grains are cleaned to separate the husk and split grains. Whole and split grains are soaked in water at ambient temperature for 25-30 minutes to produce moisture content of about 35 (%, w.b.) and then dried to 10% moisture content. The dried grains are milled in a cylindrical abrasive mill to produce dehusked split dal, which is separated from other constituents with an air-screen grain cleaner. The average recovery for pigeonpea is claimed to be 75%. This method eliminates the use of edible oil in the milling process.

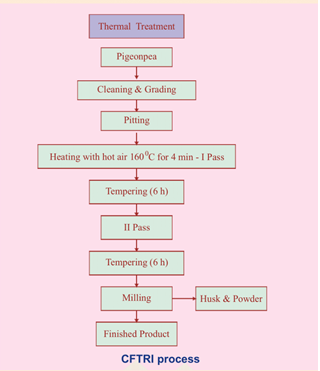

CFTRI process

The technology developed at CFTRI overcomes the major problems of weather dependent nature of pulse milling industry and gives high dalyield in lesser time. The process is independent of weather conditions and eliminates the use of oil. The loosening of husk is achieved by heating of grains in hot air current followed by tempering. Removal of husk and splitting of grains is achieved by improved processing machines. This conditioning technique through heat treatment and moisture adjustment of the cleaned, size-graded grains loosens the husk, while making it fragile and brittle besides hardening the kernels. The process involves two passes in a drier with 160 °C hot air, followed by tempering for 6 hours. The operation is continuous, replaces sun drying and carried out indoors. It is claimed that this method gives average yield of 80% dal. Many dal millers have not adopted this technique due to high electrical

energy consumption, non-availability of sufficient and continuous supply of electricity, high cost of machinery, and non-utilization of traditional milling machinery. However this method has definite advantages like less requirement of manpower, no need of drying yard, no requirement of edible oil etc., which demands due considerations.

Milling of Individual Pulses

Depending upon ease of milling, pulses are categorized in easy and difficult to mill pulses. Presence of gum layer in between seed coat and cotyledon, its quality and quantity plays an important role in dehusking process. Lentil, chickpea and peas come under easy-to-mill category, whereas pigeonpea, mungbean and urdbean fall under difficult-to-mill pulse crops. Gums and mucilage present beneath the seed coat cause adherence of seed coat with the cotyledons. Pigeonpea is considered to be the toughest-to-mill among all pulse crops. Certain pulses like pigeonpea, urdbean, mungbean, and horsegram pose great difficulty in dehusking, while pulses like chickpea, peas, lentil and khesari are relatively easy to dehusk. This difference in dehusking behaviour can be attributed to the characteristic of husk that adheres the cotyledons so tightly that poses difficulty in its removal during milling. Higher degree of attachment causes heavy milling loss in the form ofbroken and powder. Therefore, loosening ofhusk prior to milling through various treatments is an essential prerequisite.

Pigeonpea

This is the most difficult kind of pulse to mill because of tight attachment of husk to the seed coat. The clean and graded grains are pitted (scratched over the seed surface), oil smeared (0.2-0.5%), tempered for half to one day in bins, treated with water (in the ratio 1:20-25), stored overnight and sundried for 2-3 days before passing through the emery roll. Such type of husk loosening and dehusking operations are repeated 2-4 times till more than 90% grains are dehusked. Dal obtained during this method is termed as Grade-II dal as edges of most of the dal gets rounded off during milling. The mixture of dehusked and unhusked whole grain is further sprinkled with water and tempered for few hours, sundried and splitted in horizontal or vertical chakkies or by using patka machine. The dal thus obtained is considered as Grade-I dal since it has no chipped edges dal and has better customer acceptability. The recovery of pigeonpea varies from 68-75%, depending upon variety milled and method followed.

Chickpea

It falls in easy-to-mill category of pulse. Dehusking after cleaning and grading can be done in roller mills. Splitting of ‘gota' (dehusked whole grain) is carried out by treating the grain with water in ratio 1: 2.5 to 3.0, followed by tempering for 12 hours and splitting in disk sheller. This does not require oil application for loosening of husk. The process is repeated till all the grains are dehusked. Recovery from dal varies from 78–82%. Chana dal and broken can further be processed to produce besan. At household level, the burr mill is used to obtain besan. Hammer mills, which beat the dal to the particle size till it passes through the sieve of desired particle size, are employed at cottage and large scale for besan making. The recovery from these besan plants is 98% and only 2% of dal is lost due to burning and are lost in form of unrecoverable dust.

Urdbean

The process involves cleaning, grading and pitting in emery roller mills. Two or three passes will be required to complete dehusking and pitting operation. Husk and powder produced in each pass must be removed after every pass. About 0.5% oil is applied to the pitted grains, which are then stored for 12 hours. The grains are then sundried for about 2-3 days followed by water spraying in the ratio of 1:25-30 and tempered overnight. These grains are passed through rollers for dehusking. The dal splits obtained is called Grade-II dal. The ‘gota' obtained is passed through burr mill to make Grade-I quality dal. To give luster and enhance market value, dals are polished using soapstone powder.

Mungbean

It is difficult-to-mill because husk have the high degree of adherence to cotyledons. Husk is thin, soft and slippery in texture. Bond between the two cotyledons is weak, therefore, splitting occurs prior to dehusking. In order to achieve proper dehusking of mungbean grains, oil treatment is applied. Pitting, oil smearing and sun drying are followed by dehusking and splitting in roller machines. The loss in form of broken and powder is large in case of mungbean due to its thin seed coat and rubbing operation during dehusking.

Peas

This is easy to dehusk. The whole grains of peas are sold as such in the market generally after polishing to enhance the customer appeal. However, its dal is consumed in some parts of the country. The milling process includes cleaning, grading, moisture application, tempering and sun drying up to the milling moisture content (10-12%, d.b.). Dehusking and splitting can be achieved in roller mills or disk sheller. Recovery dal from peas ranges from 80–82%.

Lentil and Khesari

Both of these pulses falls in category of easy-to-mill type of pulses. The practice usually applied involves moisture addition after cleaning and grading process, followed by tempering and sun drying. Dehusking and splitting is carried out in roller machines. Dehusking process is repeated till all grains are split and dehusked.

ਆਖਰੀ ਵਾਰ ਸੰਸ਼ੋਧਿਤ : 2/19/2020

This page contains the information about the Machi...